Abstract

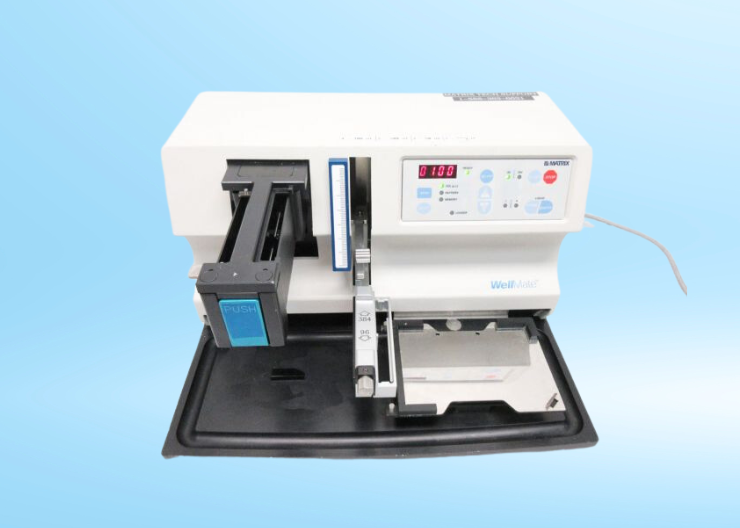

This application note discusses an approach for optimizing pipetting accuracy of a stand-alone Thermo Scientific Matrix WellMate dispenser by using the Artel MVS measurement information. The MVS supports verifying both tip-by-tip precision and accuracy values for nearly all liquid handlers.1,2 The focus of this paper is volume measurement and accuracy optimization. This application note does not speak to the quality of volume transfer performance you should expect from any WellMate. This application note will show that once volume transfer accuracy is known, it can be improved by simply tightening or loosening the adjustment screws within the 8-channel dispensing cartridge. In this study, a WellMate dispenser employing a standard 8-channel disposable cartridge was used to dispense aqueous dye solution from 5 – 350 μL. The “As Found” (initial, non-optimized) volume measurement values

were used on a channel-by-channel basis to determine if the individual adjustment screws had to be tightened (to allow less liquid to be dispensed) or loosened (to allow more liquid to be dispensed). Within minutes, the volume transfer accuracy was dramatically improved for the entire volume range, i.e., the optimized measured volumes are referred to as “As Left,” or post-optimization measurements. This example stresses that a laboratory can do more with the instrumentation that they have if there are processes for monitoring and optimizing the volume transfer performance. For instance, even bulk dispensers like the WellMate, which are typically used for non-critical dispenses, can be easily optimized to deliver important assay-specific target volumes with high accuracy.

Please fill out this brief form to download this content.